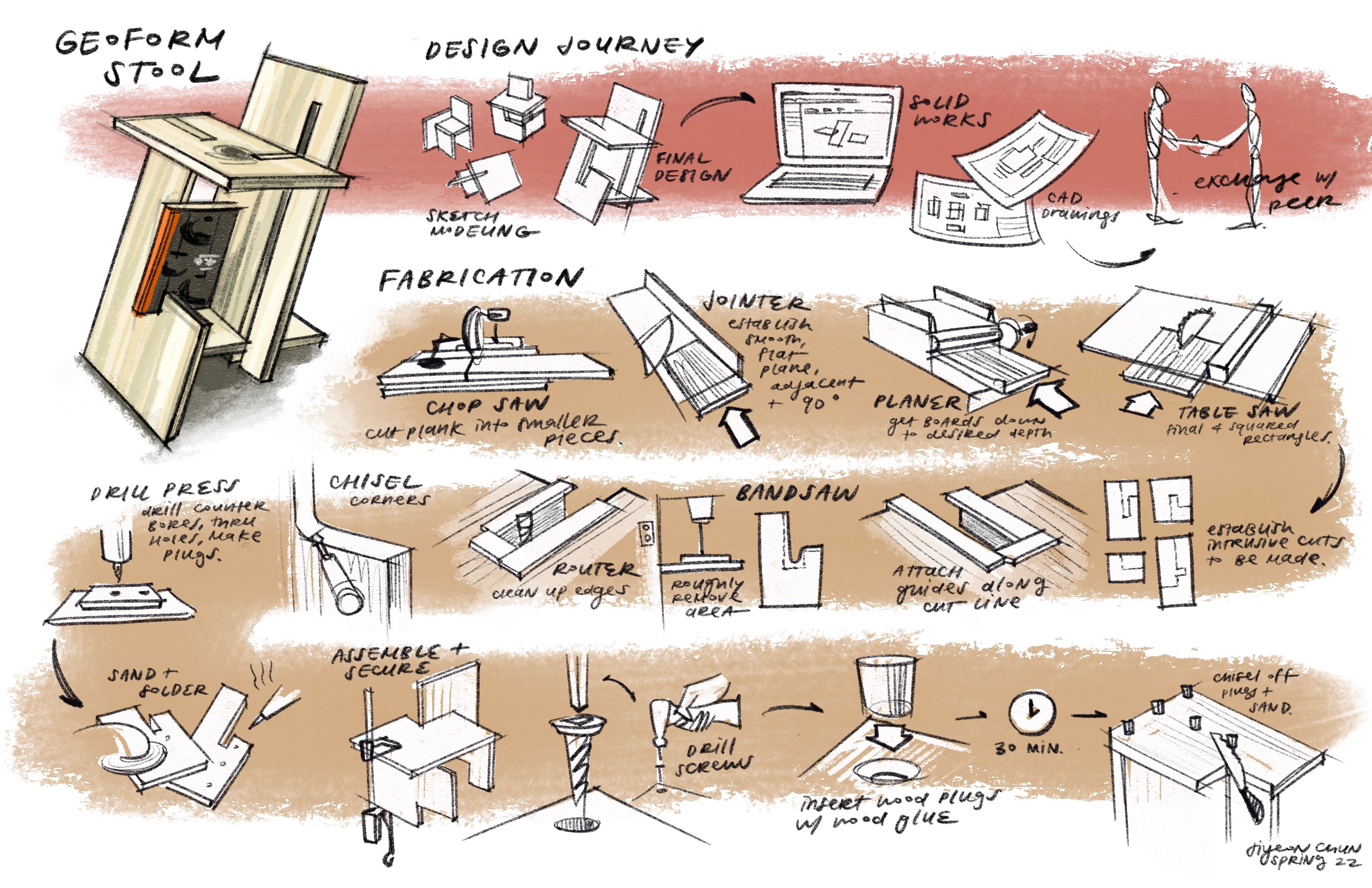

Geoform Reading Stool

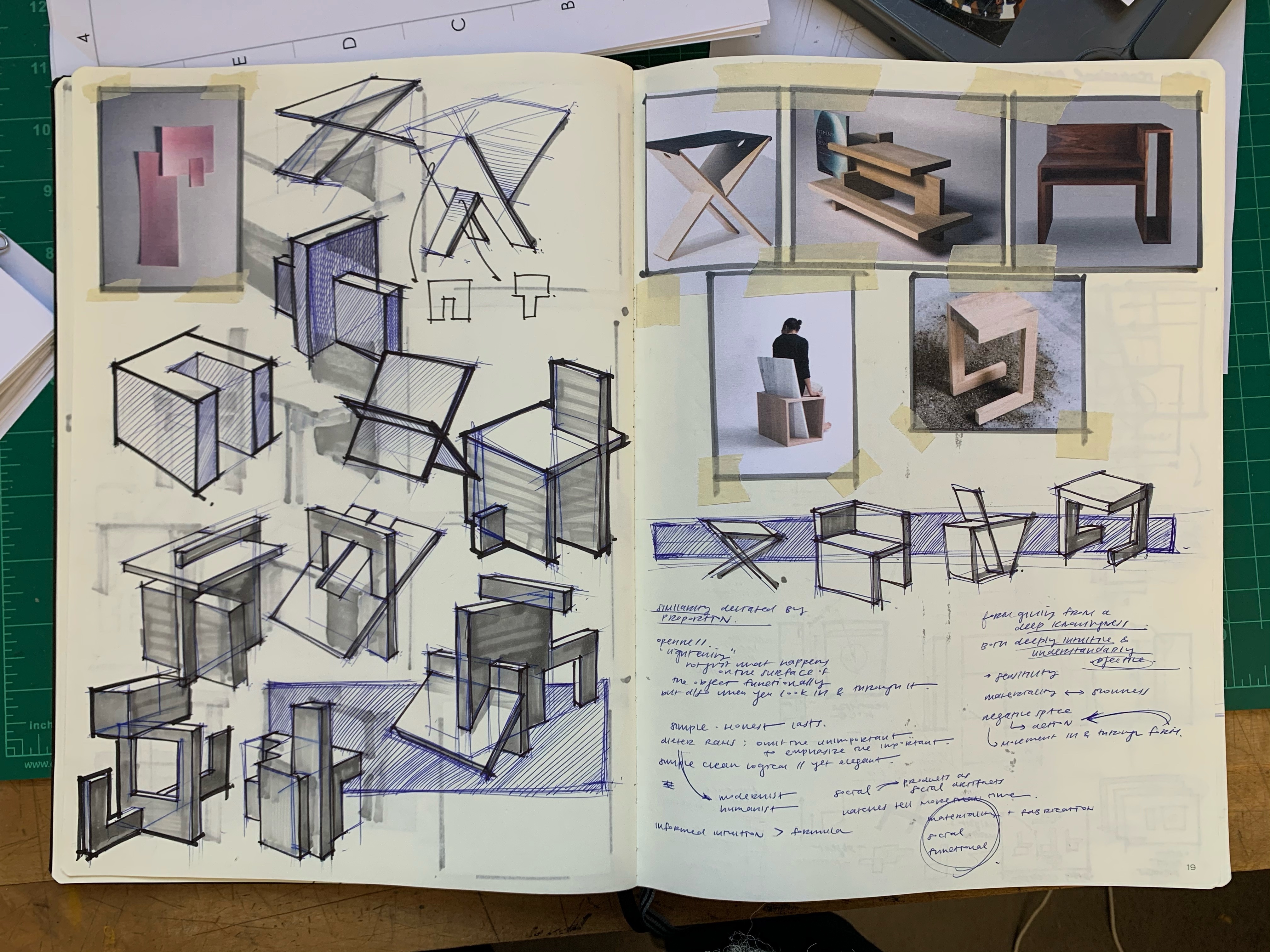

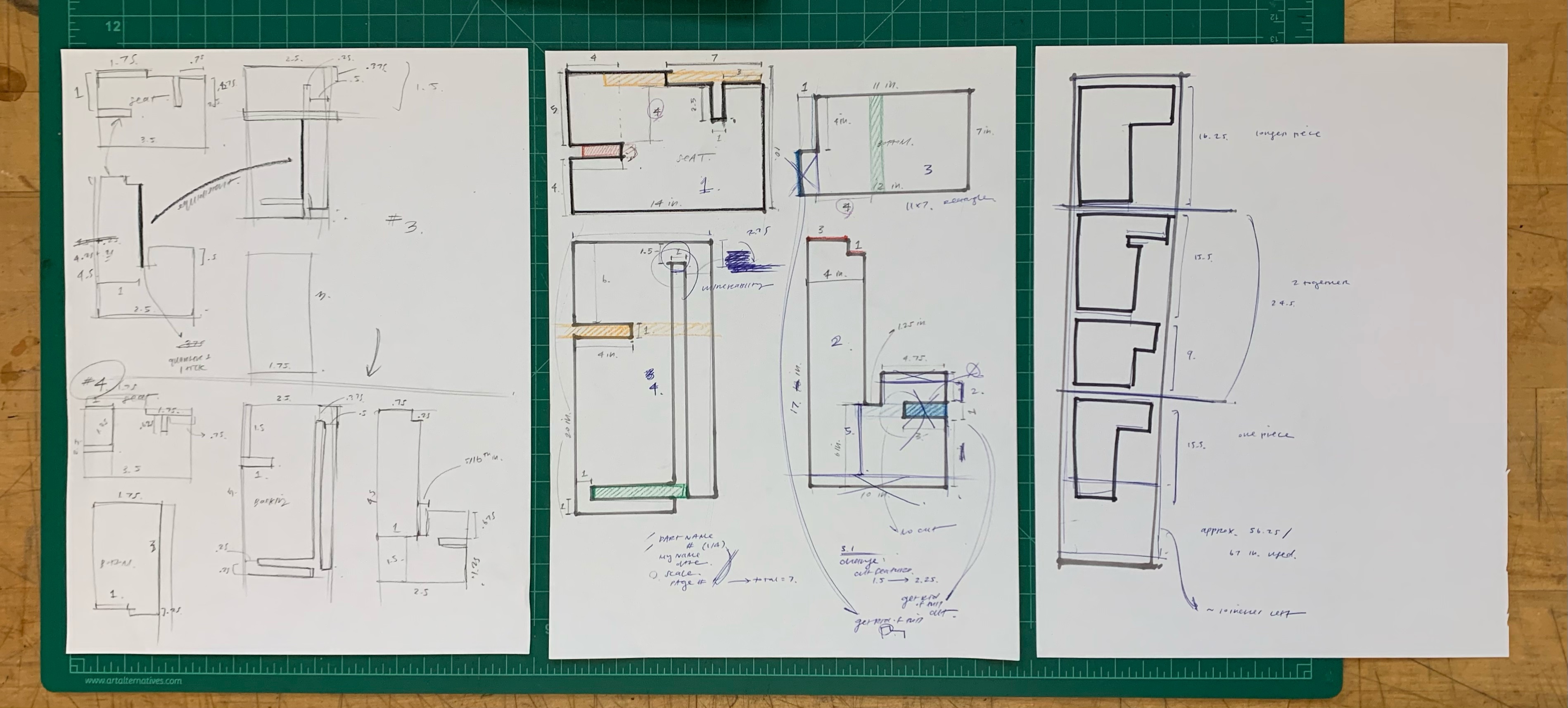

Wooden reading stool made from four boards cut from a single plank of poplar. To emulate the manufacturing process, we traded technical drawings of our own designs, fabricating another’s design and having our design fabricated by another. As an homage to our Industrial Design program, my stool features a slot to hold a book celebrating 80 years of ID at Carnegie Mellon University.

Collaborators

Julia LePoerJasper Krarup

Duration

4 Weeks, Spring 2021Course

Designing Products for InteractionMaterials

Poplar, Wood Screws, Wood GlueTools

Chop Saw, Joiner, Planer, Table Saw, Drill Press, Chisels, Router, Bandsaw, Soldering Iron, Power DrillWood-Working

Rapid Prototyping

CAD Technical Drawing

Design for Manufacturing

My stool, fabricated by Jasper Krarup.

Julia’s stool, which I fabricated.