Bend Furniture

Bend is a table and chair collection exploring the use of bent sheet metal as joinery hardware in furniture. Designed to be experimental and sculptural, yet comfortable and belong in a home.

Hand-crafted from white oak, each is held in place by a single piece of bent sheet 5052 aluminum, acting as the aesthetic and structural cornerstone of the object. They can be flat-packed and assembled with a screwdriver in under 5 minutes.

Hand-crafted from white oak, each is held in place by a single piece of bent sheet 5052 aluminum, acting as the aesthetic and structural cornerstone of the object. They can be flat-packed and assembled with a screwdriver in under 5 minutes.

Duration

14 WeeksCourse

Fundamentals of Joinery and Furniture DesignMaterials

White Oak, Bent 5052 Sheet Aluminum of Varying Finish, Threaded Inserts, Pan Head Phillips ScrewsTools

SolidWorks, Jointer, Planer, Drum Sander, Drill Press, Biscuit Joiner, Bandsaw, Table Saw, Router, Sandblaster, Steel WoolWood-Working

SolidWorks

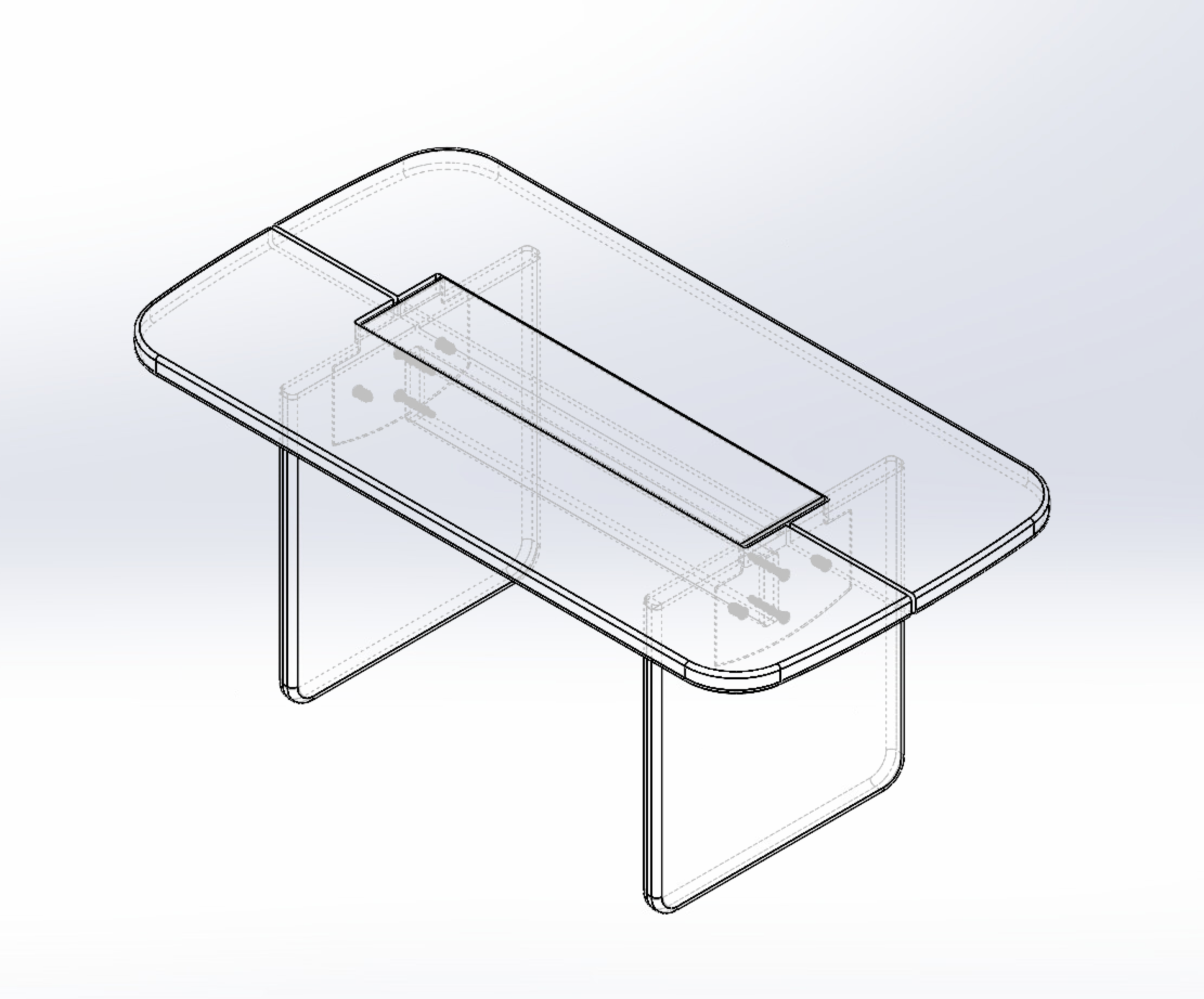

Sheet Metal CAD for Manufacture

The metal running across the table-top is visually distinct without sacrificing utility, being sand-blasted and steel-wool-ed for a finish more forgiving to scratches. The chair's backing is sturdy but with a slight give, highlighting the material affordances of the sheet metal.

Assembly

Concept

Bent sheet metal has long been used as joinery hardware in furniture; however, they usually show up as smaller pieces here and there throughout the object:

I wanted to push these boundaries by exploring a single piece of sheet metal being the driving aesthetic and strucural feature of the object.

Bent sheet metal has long been used as joinery hardware in furniture; however, they usually show up as smaller pieces here and there throughout the object:

I wanted to push these boundaries by exploring a single piece of sheet metal being the driving aesthetic and strucural feature of the object.

Table Design

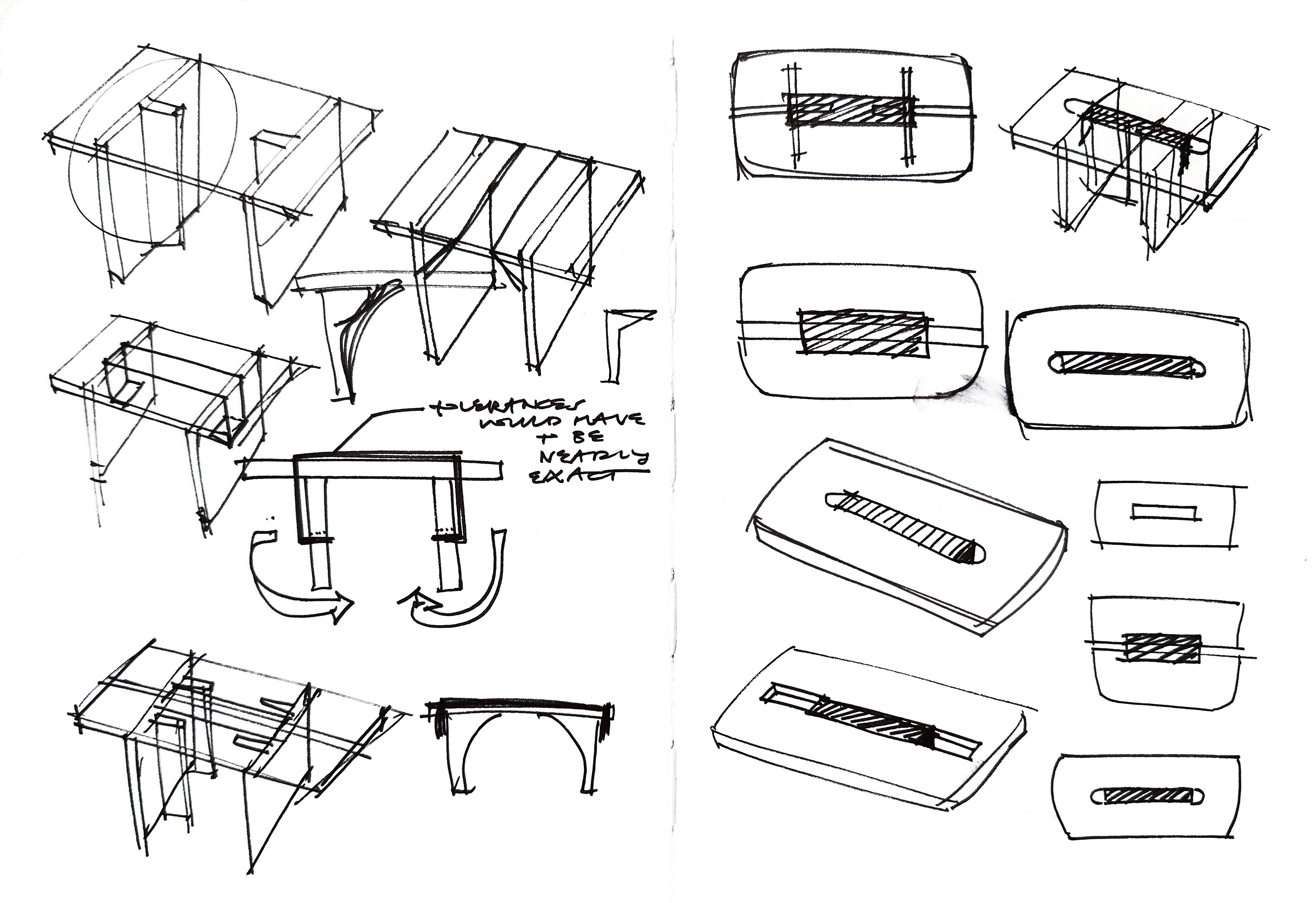

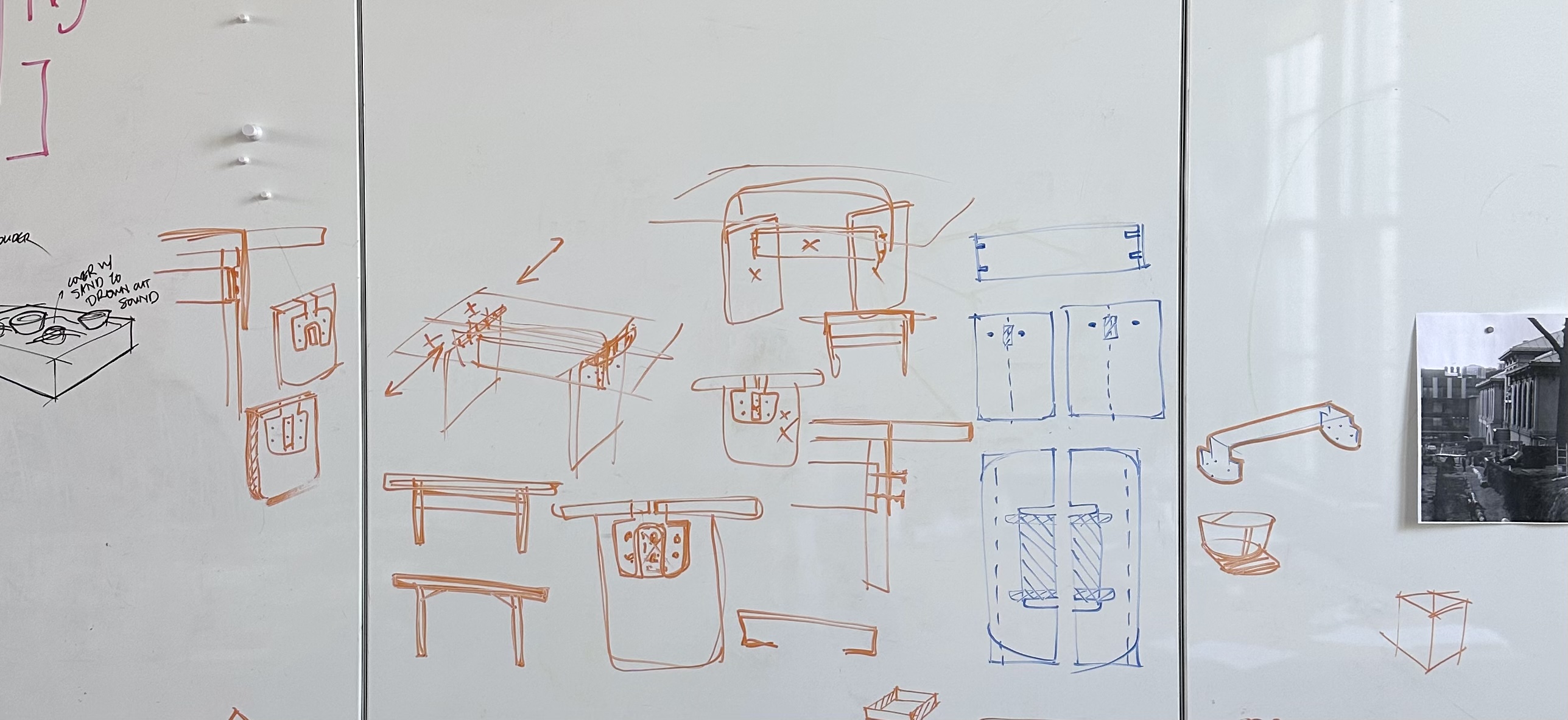

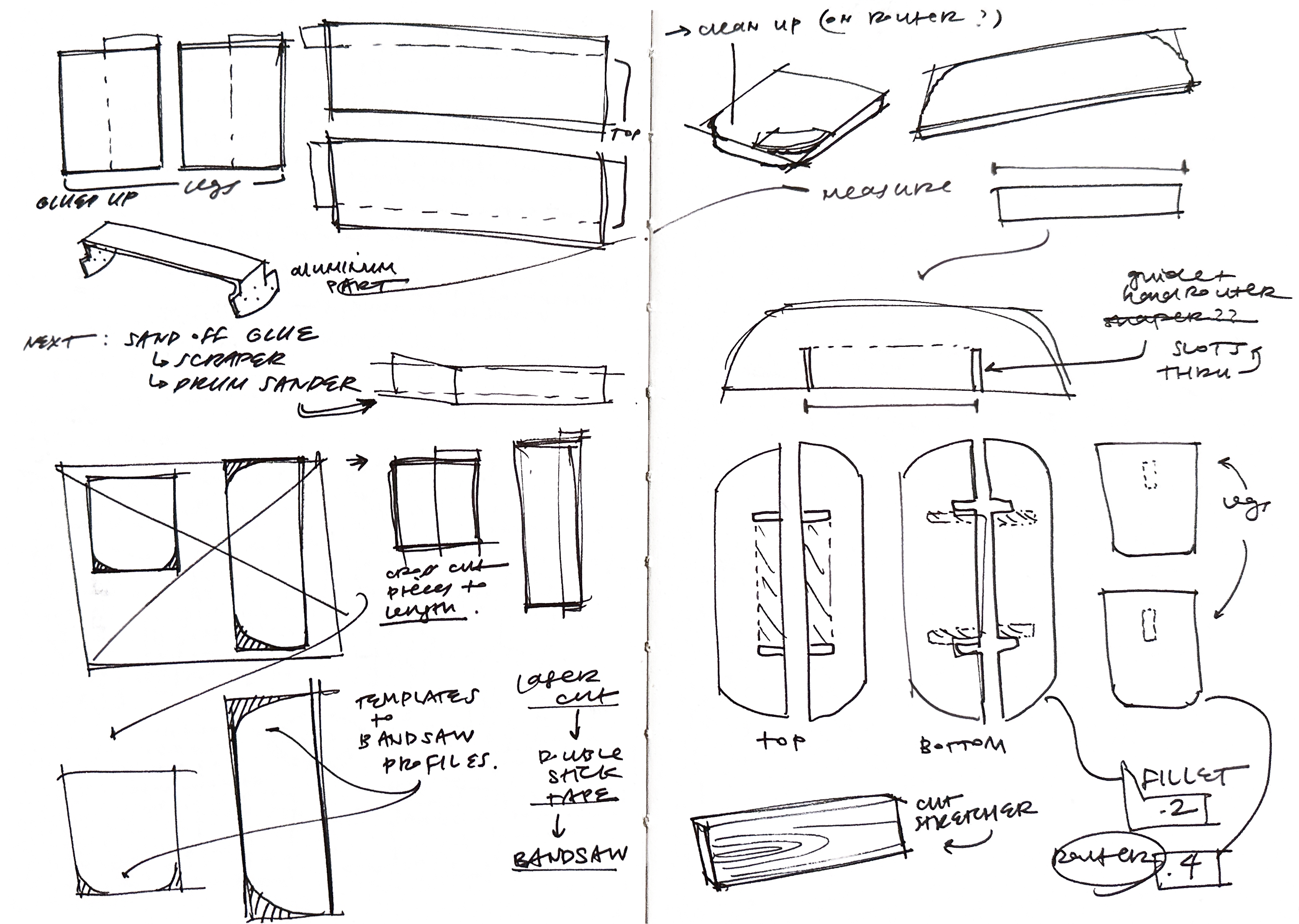

I first had the idea to “thread” a long piece of metal through openings on the tabletop while playing around with a pair of scissors and some paper.

As I sketched and thought through manufacture, assembly, functionality, and aesthetics, I landed on the slab-legs, flat stretcher, and a split across the top.

I first had the idea to “thread” a long piece of metal through openings on the tabletop while playing around with a pair of scissors and some paper.

As I sketched and thought through manufacture, assembly, functionality, and aesthetics, I landed on the slab-legs, flat stretcher, and a split across the top.

Table Refinement

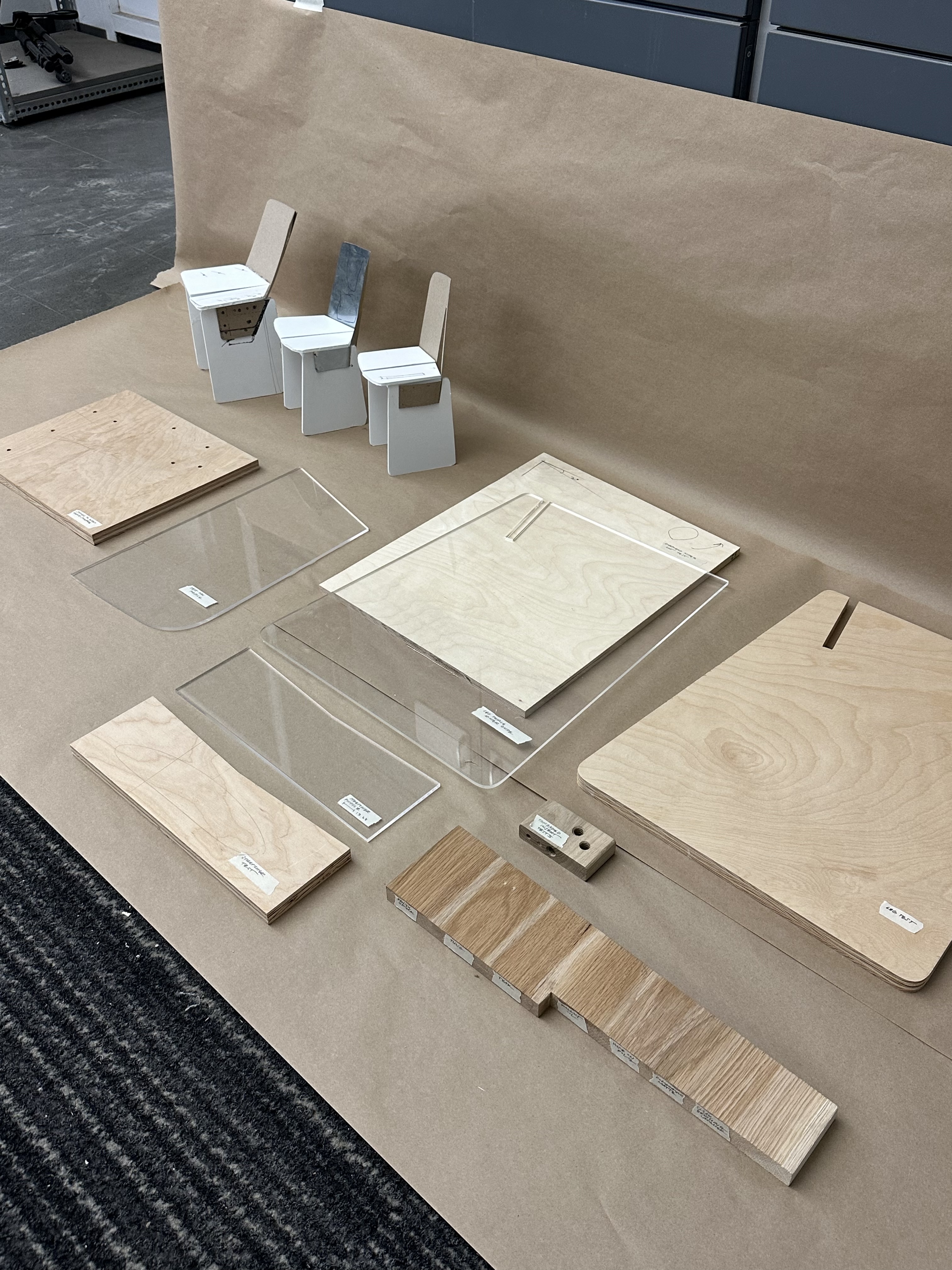

I iterated on proportions and the shape of the metal piece on Figma and SolidWorks.

I iterated on proportions and the shape of the metal piece on Figma and SolidWorks.

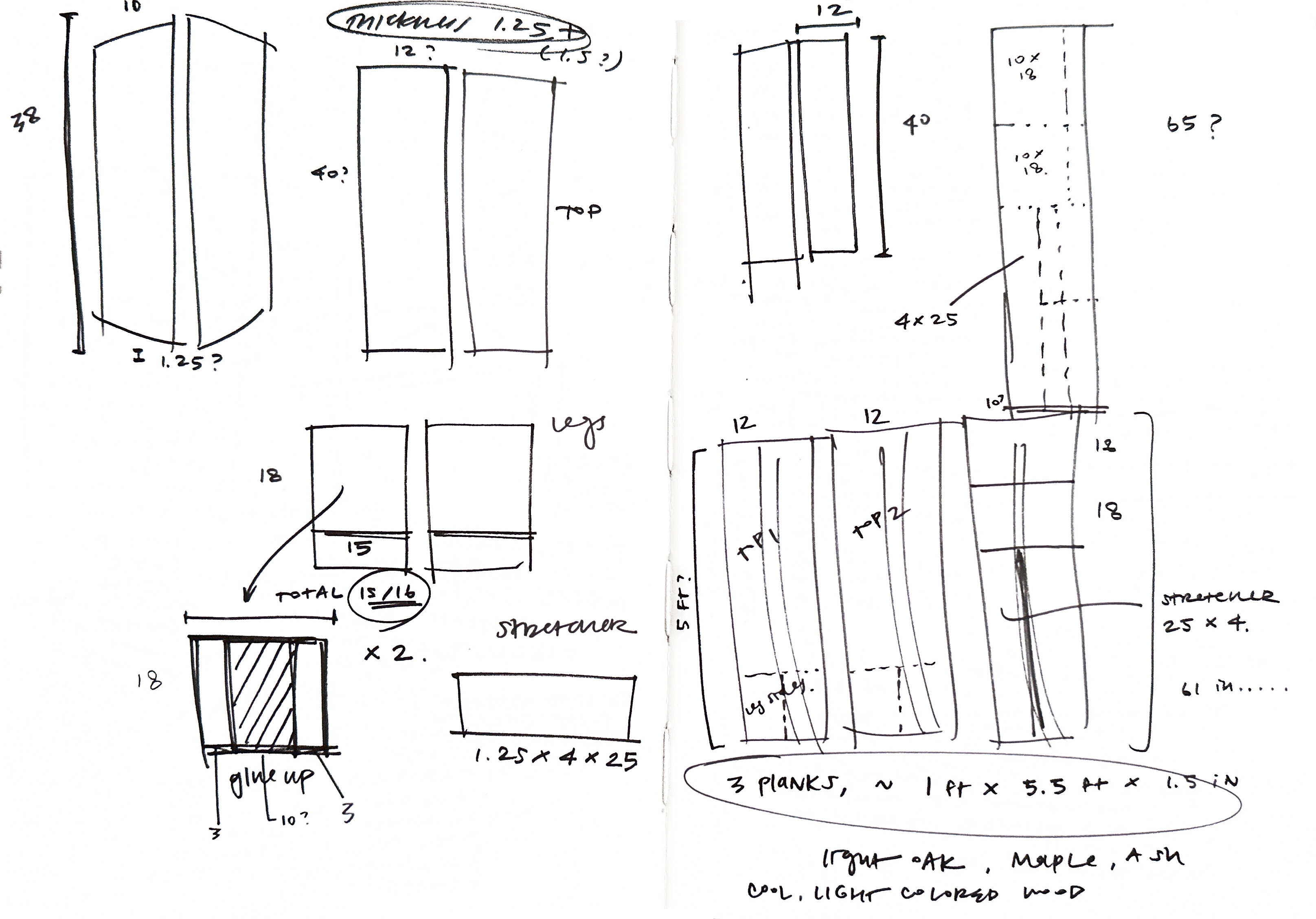

Lumber + Fabrication Plans

Making Process

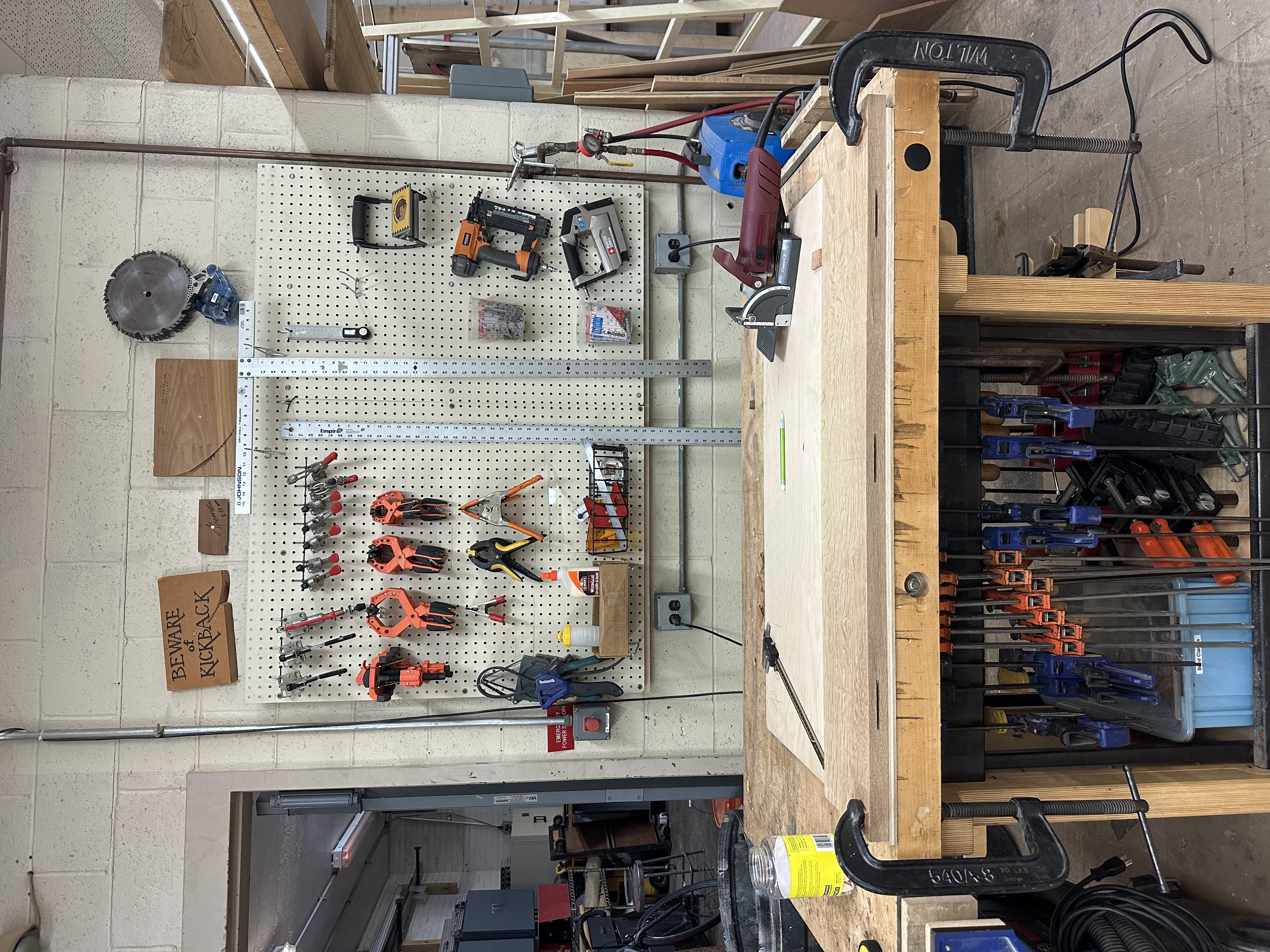

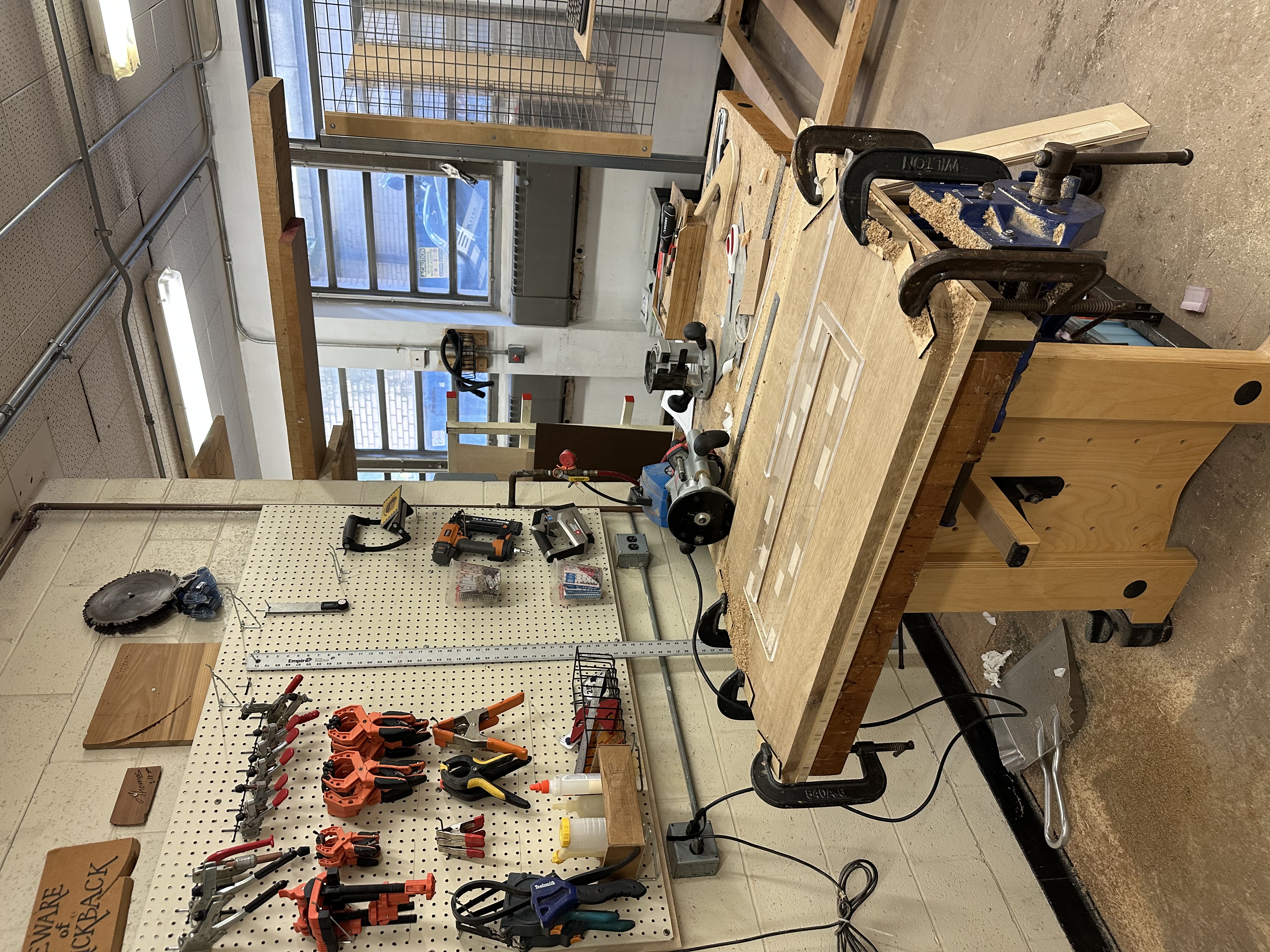

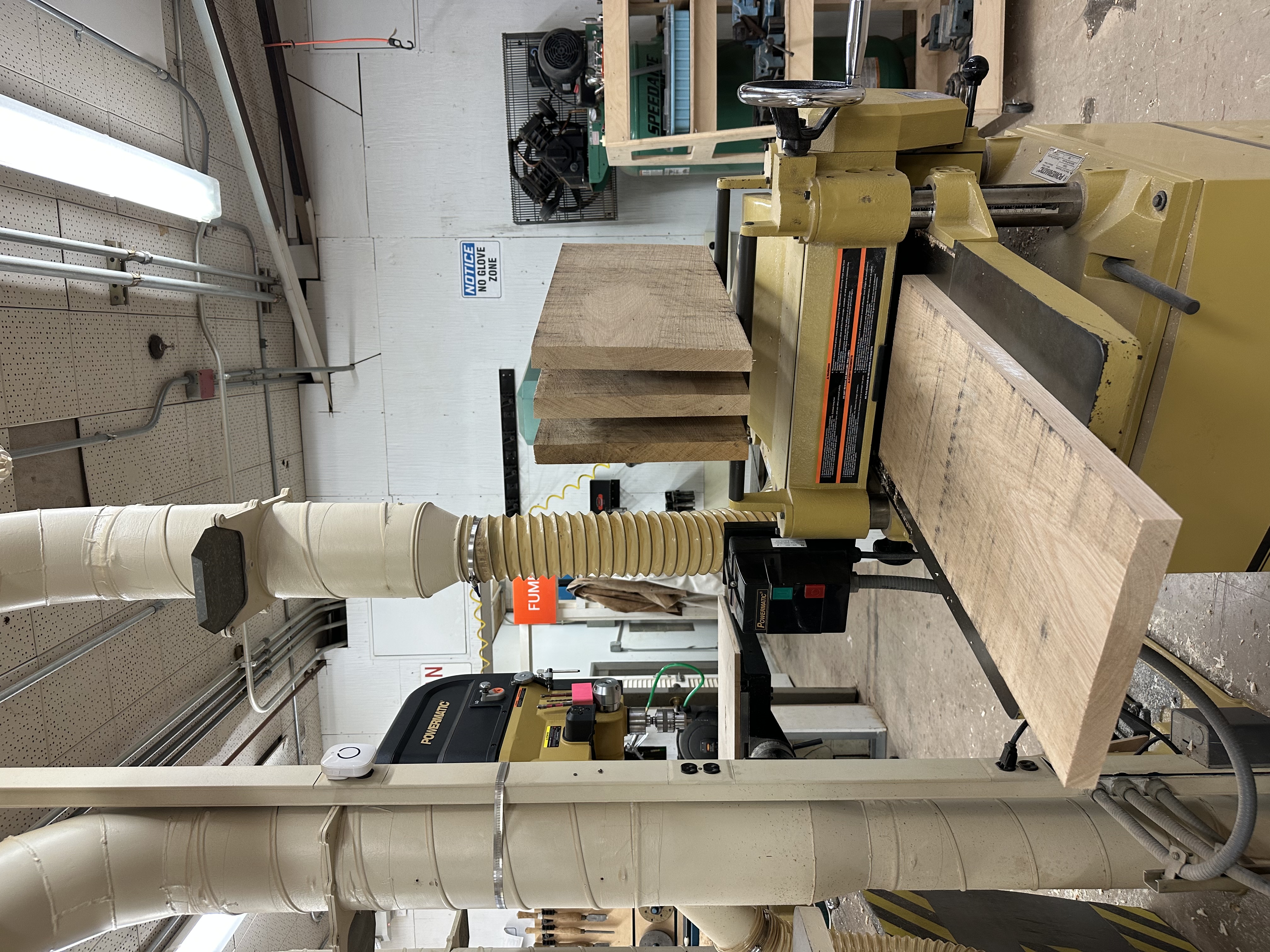

Lumber Purchase, Chop-Saw, Jointer, Planer

Biscuit Joints, Glue-Up, Drum Sander

Bandsaw and router to achieve piece profiles, hand router for fit cavities

Fillet detailing with drill press (built aluminum rod jig), chiseling for sheet metal radius fit, hardware install

Metal Manufacture + Finish

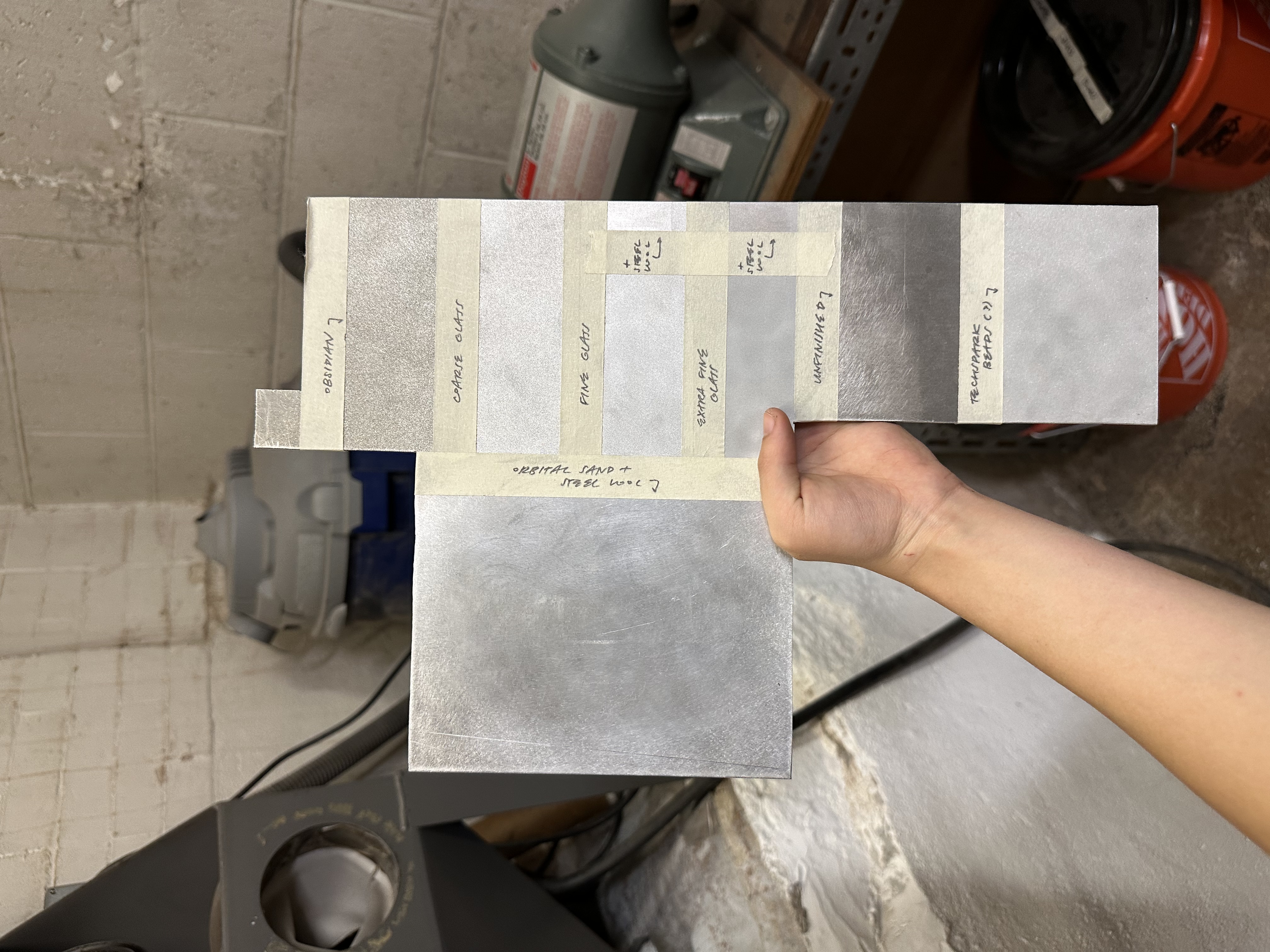

I tested a variety of different finishes on a piece of scrap aluminum. I decided on a fine bead-blast to make the surface more forgiving visually to scratches, then a steel wool finish to bring back some shine.

Once the metal part came in, I de-burred, bead-blasted, and steel wool-ed the piece by hand.

I tested a variety of different finishes on a piece of scrap aluminum. I decided on a fine bead-blast to make the surface more forgiving visually to scratches, then a steel wool finish to bring back some shine.

Once the metal part came in, I de-burred, bead-blasted, and steel wool-ed the piece by hand.

Chair Sketches

For the chair, I started with a trip to the Carnegie Museum of Art and their exhibition of functional objects “Extraordinary Ordinary Things,” and preliminary ideas for combining wood and sheet metal again.

For the chair, I started with a trip to the Carnegie Museum of Art and their exhibition of functional objects “Extraordinary Ordinary Things,” and preliminary ideas for combining wood and sheet metal again.

Chair

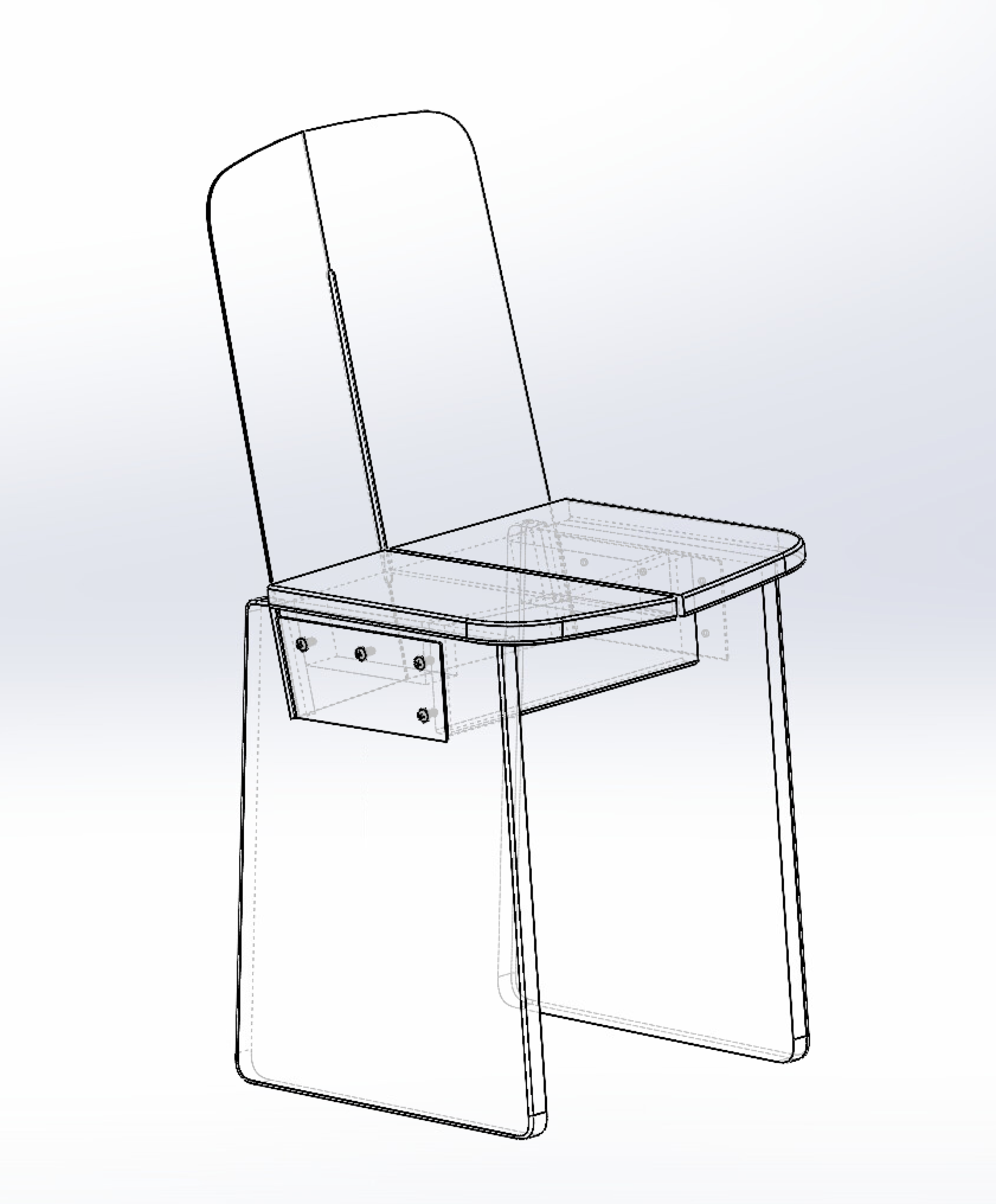

I realized that the flexibility of sheet metal would make it appropriate material for the back rest, and began to think of how one back-rest piece could fold over to hold together the other parts of a chair.

I briefly considered using steel for its high(er) flexibility, but soon realized its weight made it unsuitable.

I realized that the flexibility of sheet metal would make it appropriate material for the back rest, and began to think of how one back-rest piece could fold over to hold together the other parts of a chair.

I briefly considered using steel for its high(er) flexibility, but soon realized its weight made it unsuitable.

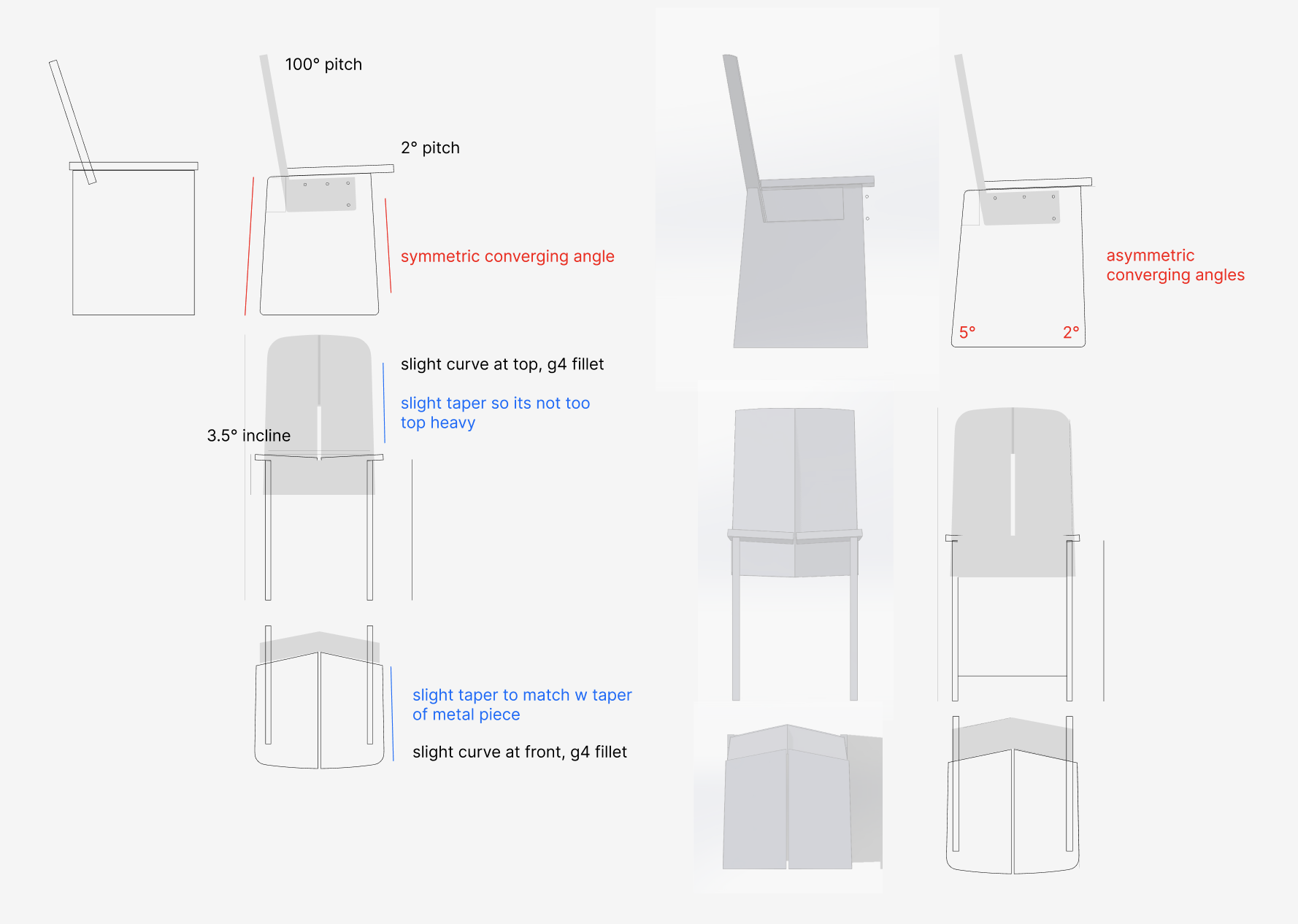

Refinement + Ergonomics

The chair came with challenges unique from the table because of ergonomics and the need to support human weight. Timeline didn’t afford building my own ergonomics prototypes, so I took measurements from a variety of sensible desk and dining chairs and referenced those.

I wanted to keep it slab-like and rudimentary, with the same slight curves and fillets as the table. I incorporated angles only where most necessary to create a comfortable seating position, while maintaining square relations everywhere else in order to simplify fabrication, alignment, and assembly.

I iterated through to the final form with sketching, models, Figma, and SolidWorks.

The chair came with challenges unique from the table because of ergonomics and the need to support human weight. Timeline didn’t afford building my own ergonomics prototypes, so I took measurements from a variety of sensible desk and dining chairs and referenced those.

I wanted to keep it slab-like and rudimentary, with the same slight curves and fillets as the table. I incorporated angles only where most necessary to create a comfortable seating position, while maintaining square relations everywhere else in order to simplify fabrication, alignment, and assembly.

I iterated through to the final form with sketching, models, Figma, and SolidWorks.

Making Process

Chop saw, jointer, planer

Biscuit jointer, glue-up

Compound miter cuts, router, chisel

Alignment, hardware install, assembly

Finish

From left to right: soldering dents, final sanding, testing wood finishes, and applying paste wax to metal pieces.

From left to right: soldering dents, final sanding, testing wood finishes, and applying paste wax to metal pieces.

Special thanks to Matt Zywica, Josiah Stadelmeier, Hali Simmons, John and Ed at Techspark, and Dylan Vitone.

and the most wonderful class of peers ever <3