AIRSAFE Gas Detection

Sponsored Project with Industrial Scientific Company

The AIRSAFE Gas Detection System is a reconceptualization of one of ISC’s current product systems. Ergonomic, intuitive, and beautiful, the devices inspire a more personal relationship between worker and tool.

The AIRSAFE Gas Detection System is a reconceptualization of one of ISC’s current product systems. Ergonomic, intuitive, and beautiful, the devices inspire a more personal relationship between worker and tool.

Duration

7 Weeks, Fall 2022Group Members

Georgia MillerJayden Liu

My Role

Radius BZ1 Area Monitor, UI Re-Design, Rendering Final System ImagesProblem Framing

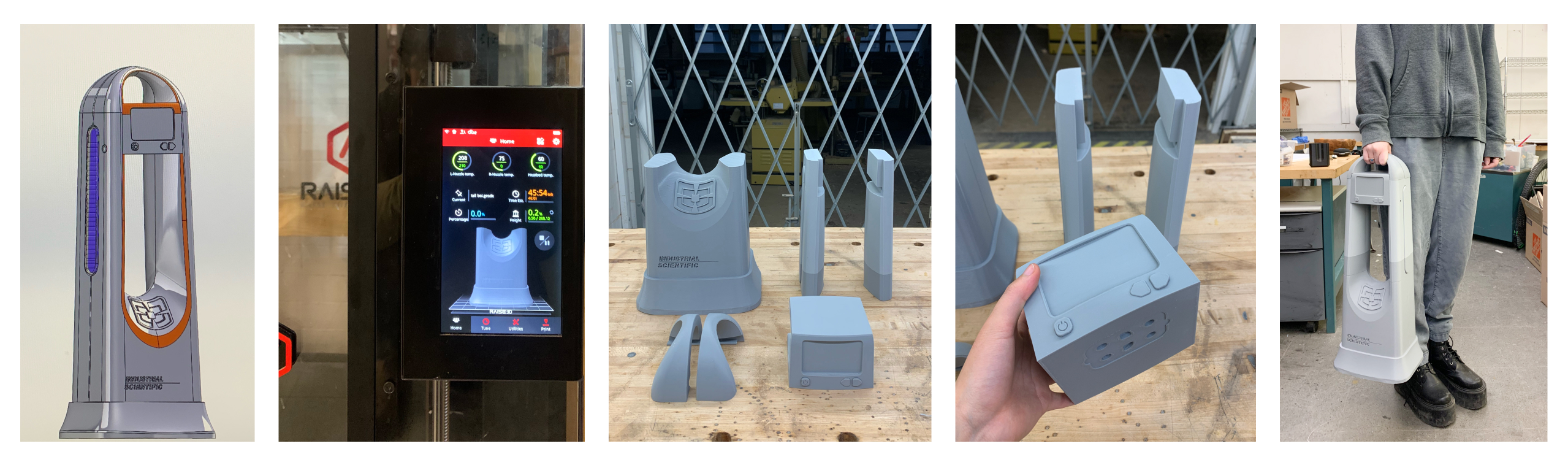

Rapid Prototyping

Visual Brand Language

CAD Modeling and 3D Printing

Digital Rendering

UI Design

Final Product System

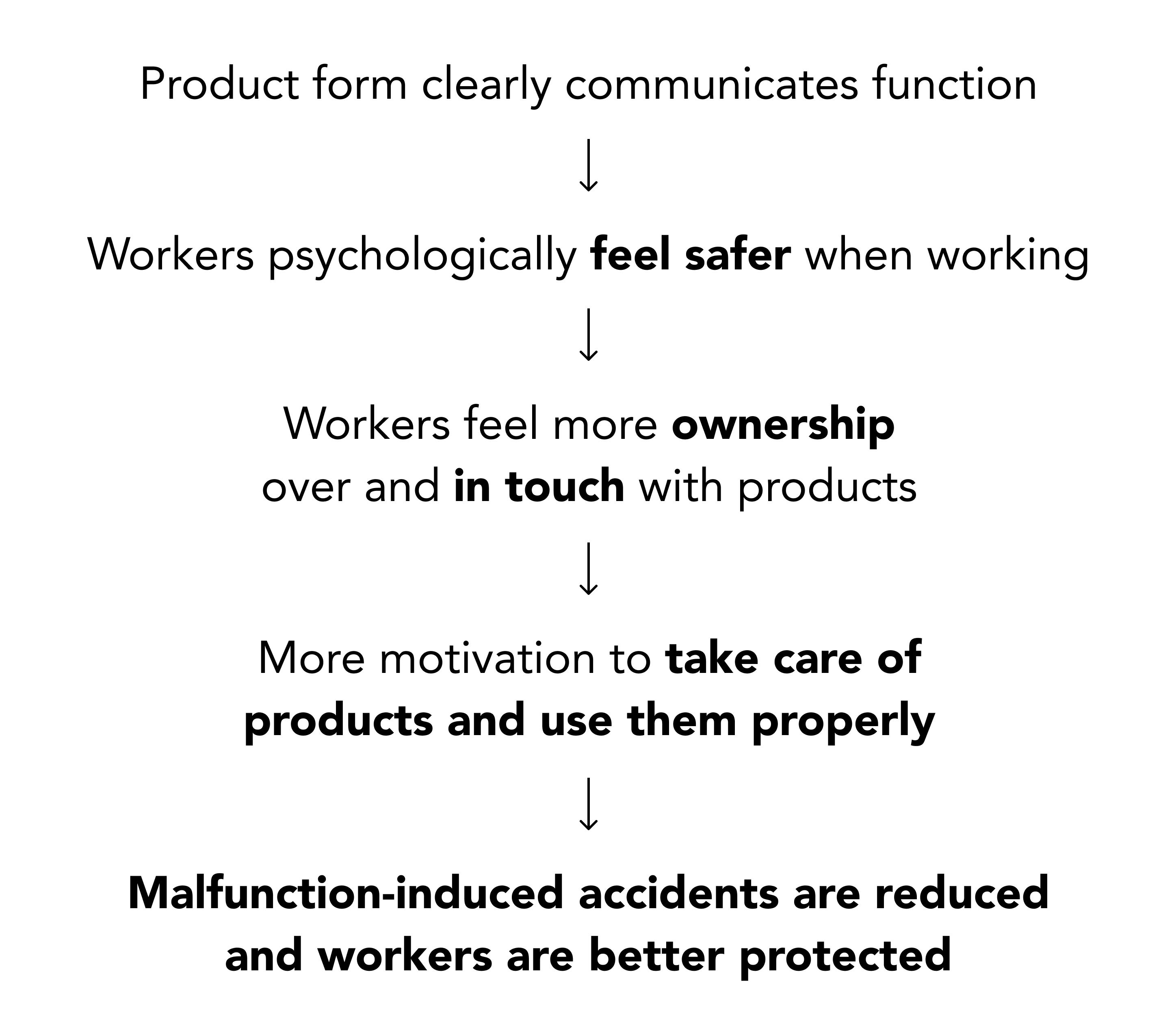

Each product form intuitively communicates its function, helping workers feel safer onsite and more connected to their tools. I specifically focused on redesigning the Area Monitor.

Background

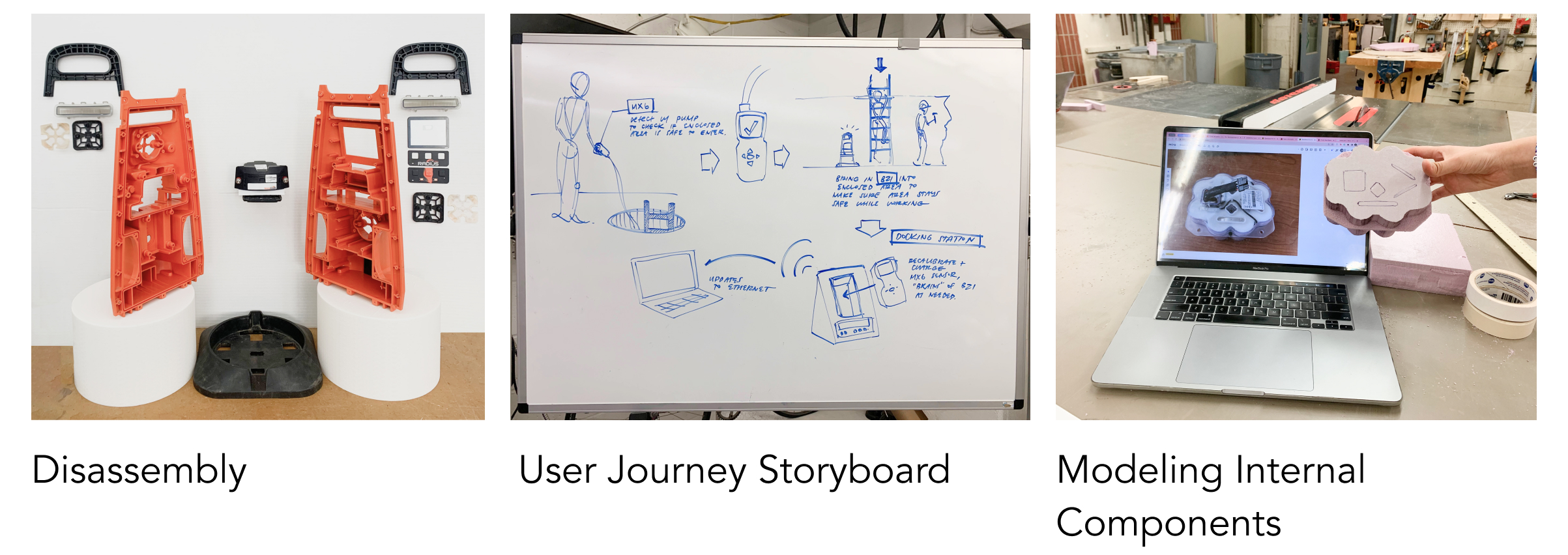

At the start of the project, ISC invited us to their headquarters in Pittsburgh for a tour— and to help imagine what the next generation of gas detectors could be. Our group focused on redesigning one of their current product systems which includes:

After gaining a better understanding of the products:

![]()

We identified a few design opportunities for the overall system:

- Products are overall heavy and bulky

- Radius, DSX forms make them un-stackable and not able to be transported compactly

- Button orientations are uncomfortable and unintuitive

- Products are almost purely functional and task-focused, not very pleasing or satisfying to use

- In-cohesive UI

Opportunity

We also learned through provided research that at the core, a key problem is that many workers view the products as a tedious box to check off out of obligation instead of as a valuable tool — decreasing motivation for thorough use and proper maintenance.

“Help me feel in touch with my tools so that I can feel safe doing my job.”

“Complicated tools make me feel unmotivated to use them properly.”

“At the end of a long day, the last thing I want to do is bump test my device.”

“Help me feel like my gas monitor is a valuable tool.”

︎︎︎ Thus, we wanted to help workers develop a more trusting and personal connection to their tools.

Scope

At the same time, we recognized that our products should still be grounded in the realities of manufacturing, the rough nature of the work, and the industry’s strict safety requirements.

Thus, we didn’t want function and hardware to deviate radically, and chose to focus primarily on form, asking the question:

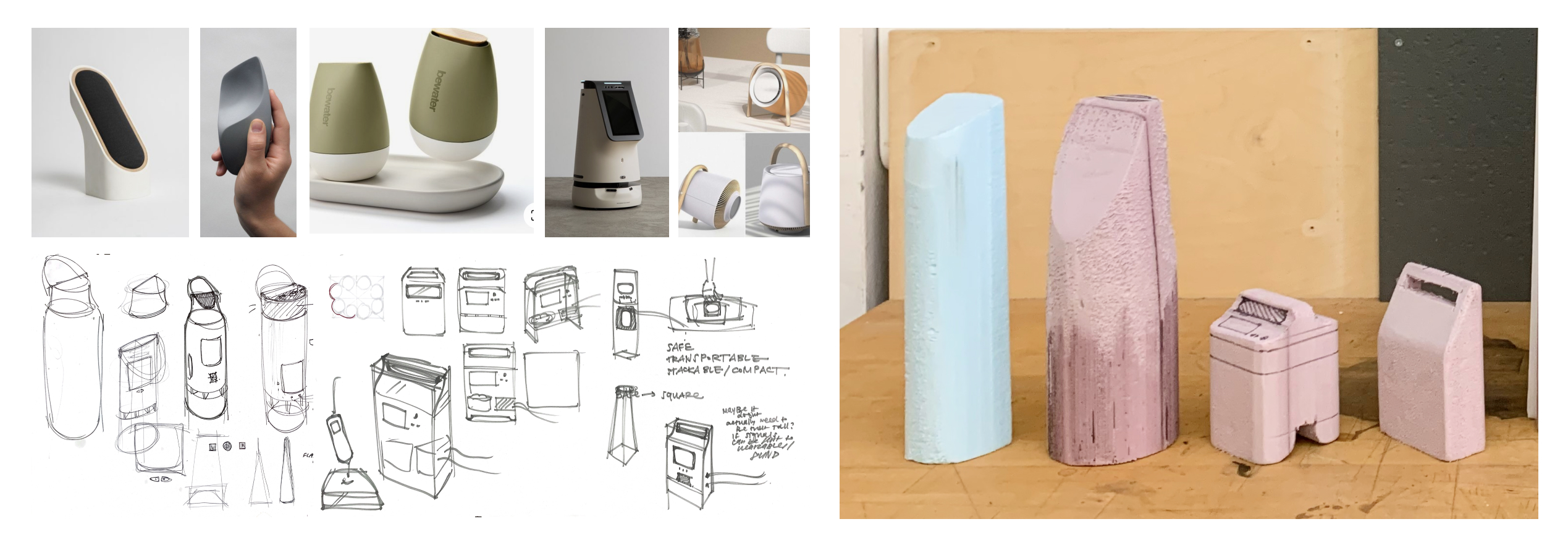

Inspiration, Preliminary Sketches and Models

Though we started off by looking at inspiration images and sketching through how the products could “look better”, we soon realized that beyond making something more beautiful or ergonomic, a product form that feels trustworthy is one that clearly communicates its function.

Concept Exploration

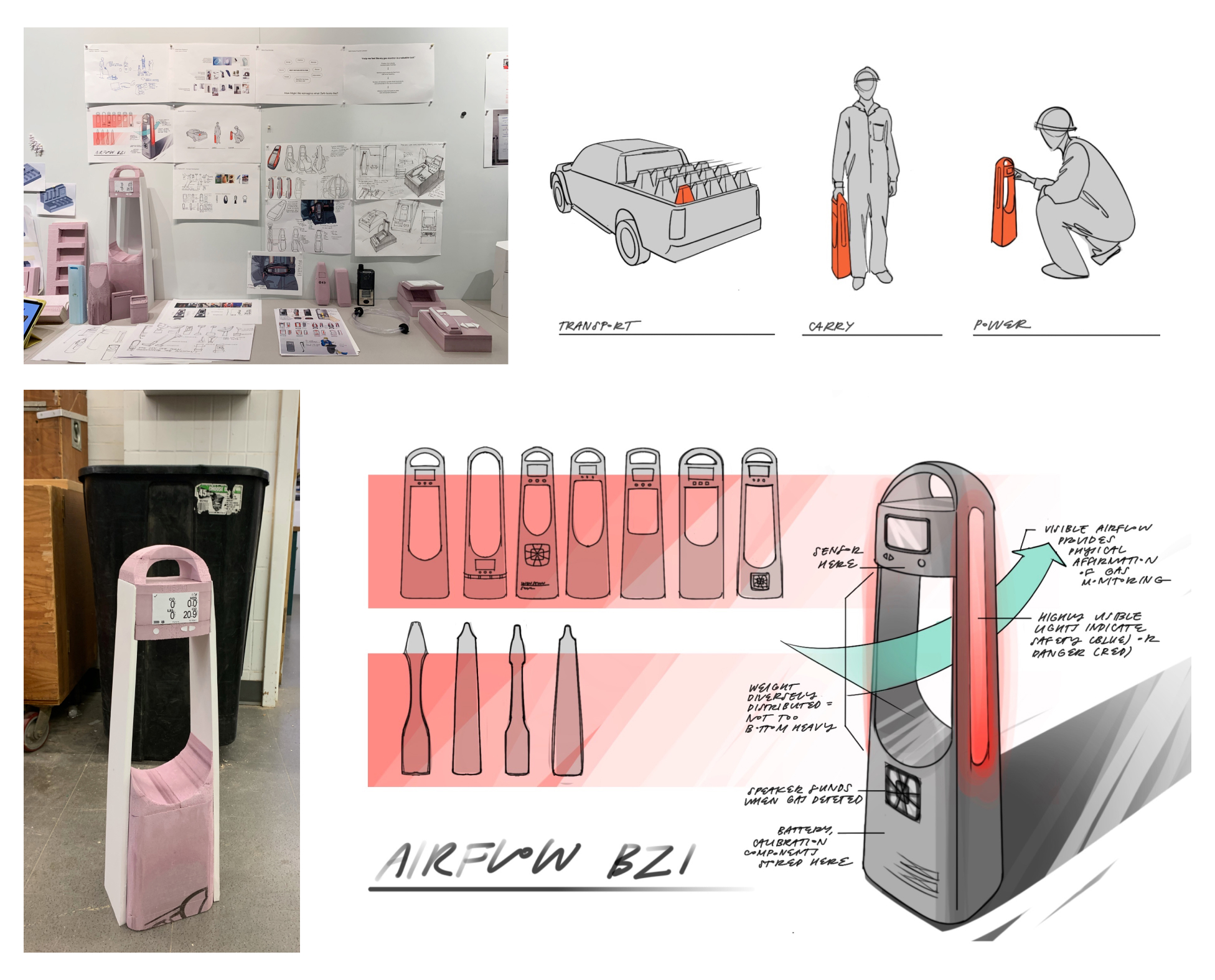

Fantastical explorations about forms that communicate collecting and monitoring led me to reference bladeless fans, which provide a clear visual indication of airflow.

Design Intent

Interim Presentation

For the interim presentation, the goal was to brief the ISC contacts on our decided concept with sketches and full-scale models.

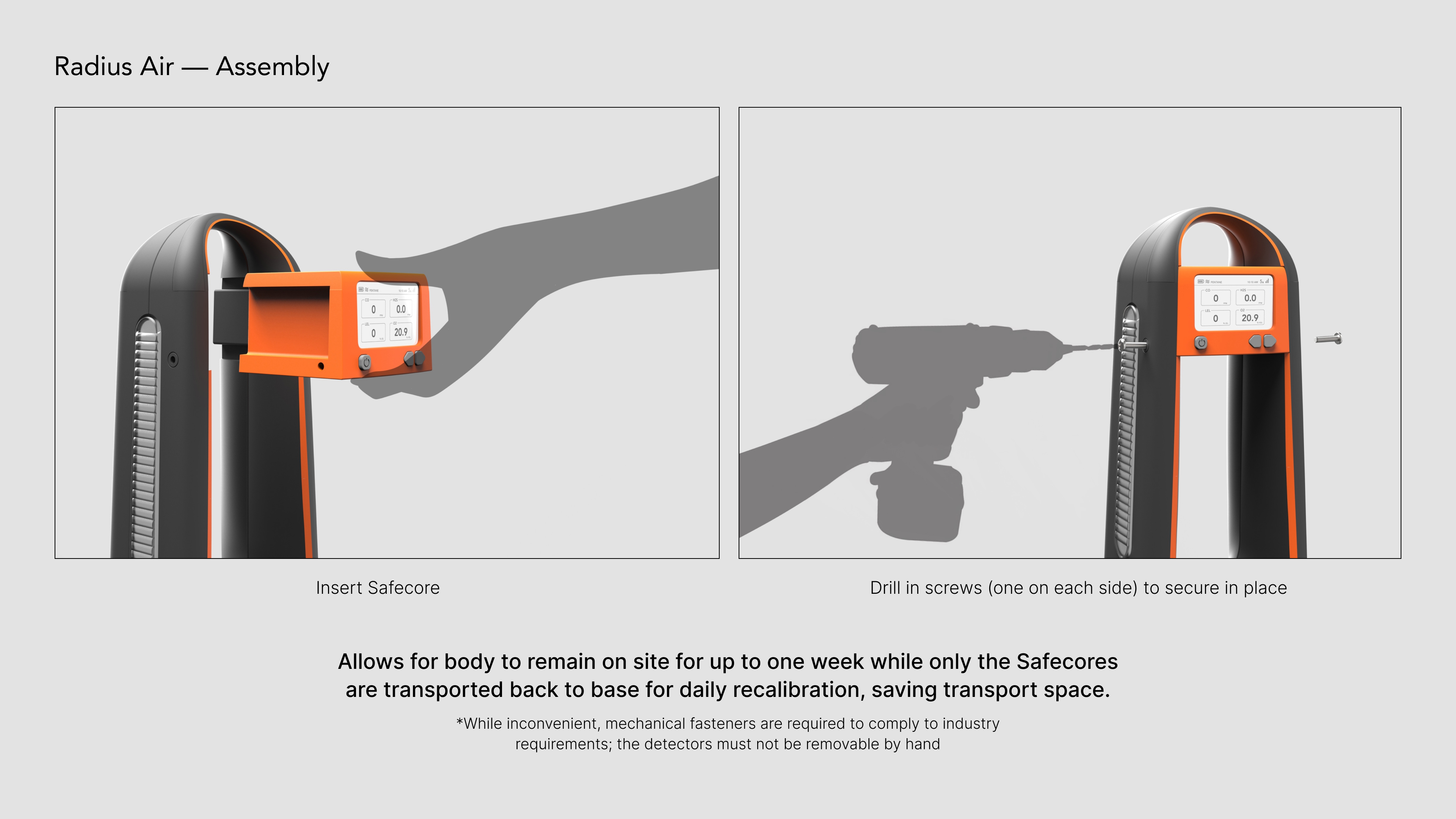

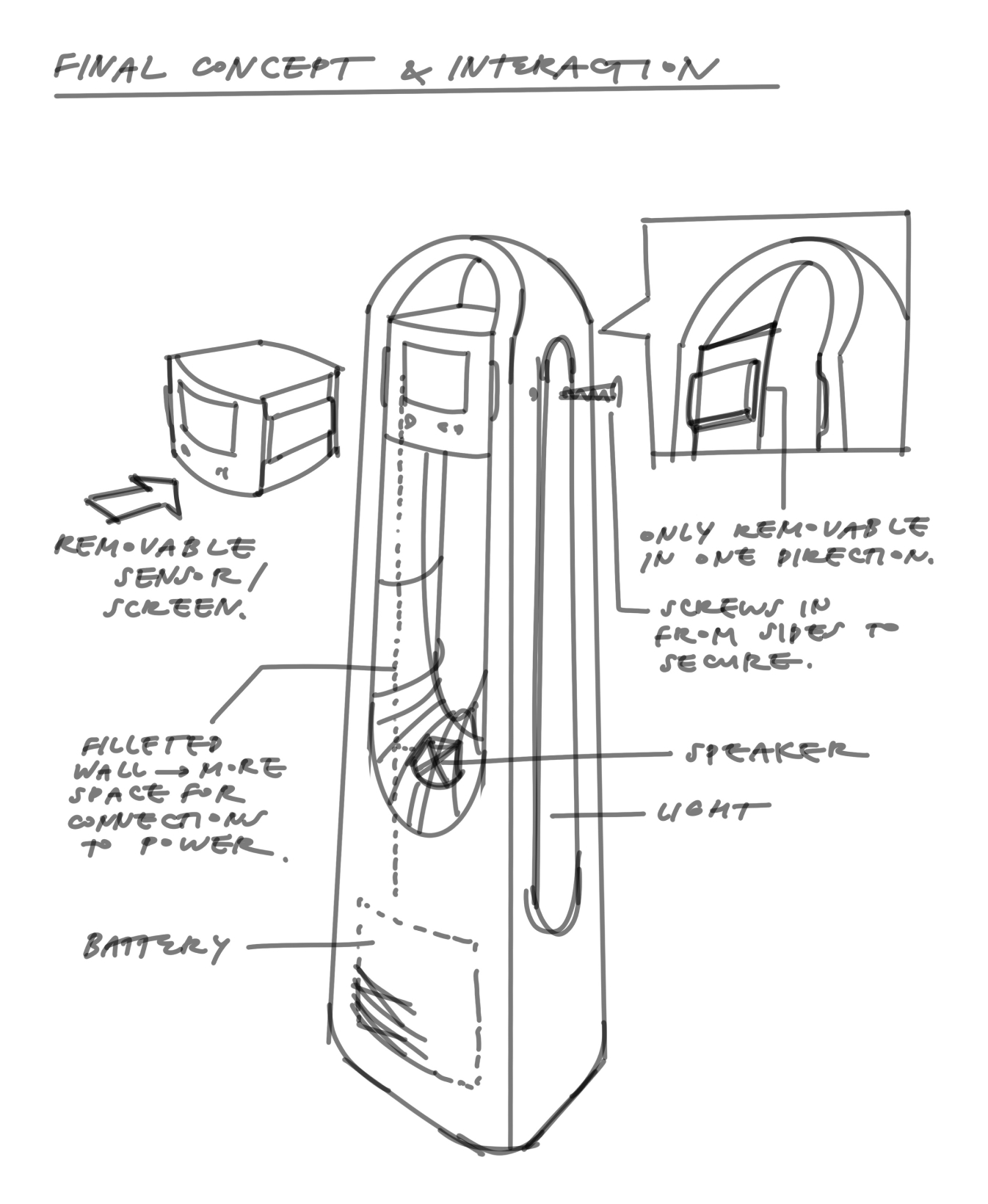

Final Interaction

The final concept includes a removable SafeCore that is engineered to move in/out from one side only and is secured using two screws.

Thicker, filleted walls curb vulnerability and make room for wires that need to run from the battery below to power the SafeCore above.

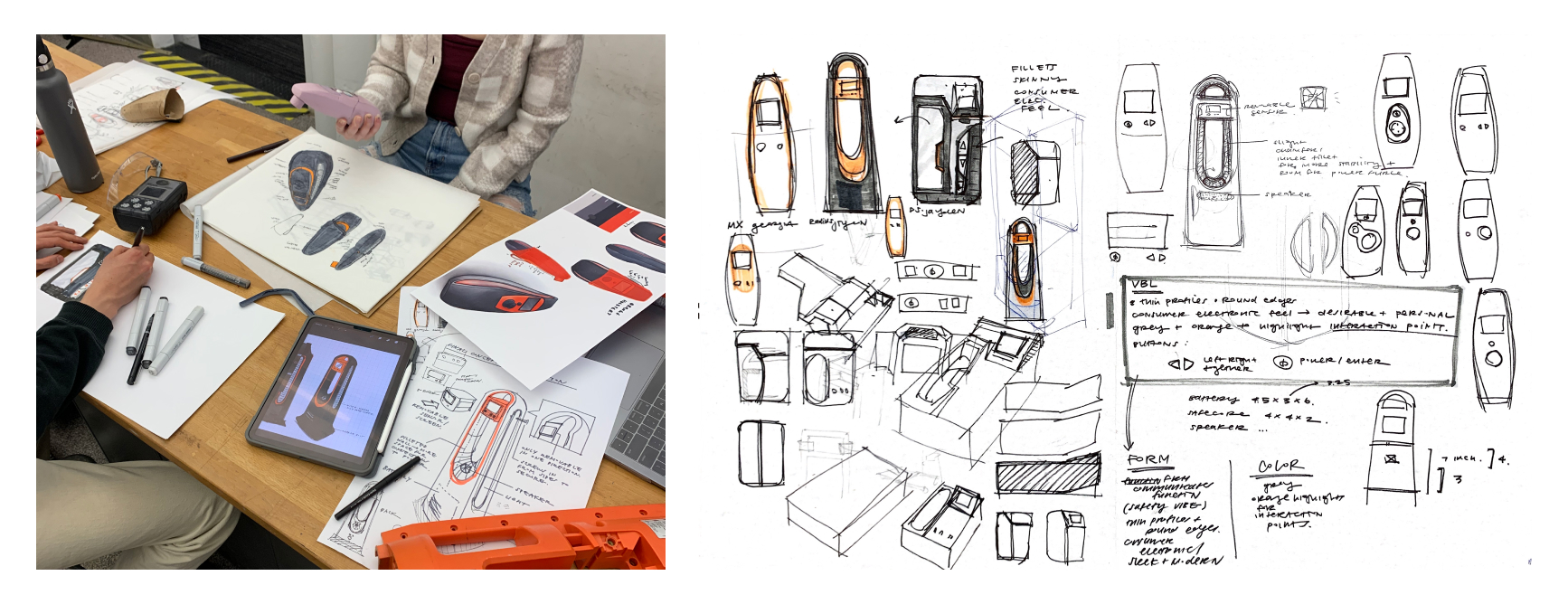

Visual Brand Language

At the same time, we made decisions as a team to give our products a cohesive brand language.

We decided to lean in to a consumer electronic look with thin profiles and rounded edges to make the products feel more personal, consumer-driven, and desirable.

Orange would be used as to highlight the interaction/function points instead of as the main color, which may communicate a sense of danger at all times.

Form Development

I worked between physical protyping, CAD, scaled sketching, and 3D Printing to reach my final form.

Final Form Model

We printed the final model in six different pieces for efficiency, and I used acrylic glue to assemble them together. Total time printing was approximately 180 hours.